-

×

NEW Agilent Varian IDP-3 Dry Oil-Free Scroll Vacuum Pump With Inlet Valve Kit PN IDP3A21, 220 VAC

2 × $3,630.54

NEW Agilent Varian IDP-3 Dry Oil-Free Scroll Vacuum Pump With Inlet Valve Kit PN IDP3A21, 220 VAC

2 × $3,630.54 -

×

Adapter KF-25 (QF) to 1/8 NPT-Male, Flange ISO-KF NW-25, Stainless Steel Hardware

1 × $38.50

Adapter KF-25 (QF) to 1/8 NPT-Male, Flange ISO-KF NW-25, Stainless Steel Hardware

1 × $38.50 -

×

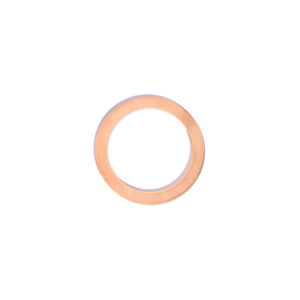

Copper Gasket, CF 63, 4-1/2", Package of 1 High Vacuum Gasket, CF-63 UHV Gasket

1 × $4.40

Copper Gasket, CF 63, 4-1/2", Package of 1 High Vacuum Gasket, CF-63 UHV Gasket

1 × $4.40 -

×

NEW Agilent Varian TriScroll 300 Oil-Free Dry Scroll Vacuum Pumps 1-Phase Motor PTS03001UNIV

1 × $6,302.70

NEW Agilent Varian TriScroll 300 Oil-Free Dry Scroll Vacuum Pumps 1-Phase Motor PTS03001UNIV

1 × $6,302.70 -

×

Oerlikon Leybold D16BXP, Explosion Proof Motor TriVac Series Rotary Vacuum Pumps, 1-Phase 115/220VAC

1 × $7,893.33

Oerlikon Leybold D16BXP, Explosion Proof Motor TriVac Series Rotary Vacuum Pumps, 1-Phase 115/220VAC

1 × $7,893.33 -

×

NEW Pfeiffer TVF 005 Vent Valve, G-1/8 connection w/ M8 plugin for HiPace 80 or 300 PN PMZ01290

1 × $1,137.25

NEW Pfeiffer TVF 005 Vent Valve, G-1/8 connection w/ M8 plugin for HiPace 80 or 300 PN PMZ01290

1 × $1,137.25 -

×

SM-S160 Metal 3D Printer

1 × $42,500.00

SM-S160 Metal 3D Printer

1 × $42,500.00 -

×

Edwards STP-iX455 5-axis Magnetic Bearing Turbo-Molecular Pump ISO160K, LF160 Inlet

1 × $15,598.08

Edwards STP-iX455 5-axis Magnetic Bearing Turbo-Molecular Pump ISO160K, LF160 Inlet

1 × $15,598.08

Subtotal: $80,735.34

-300x300.jpg)