No products in the cart.

Edwards Vacuum

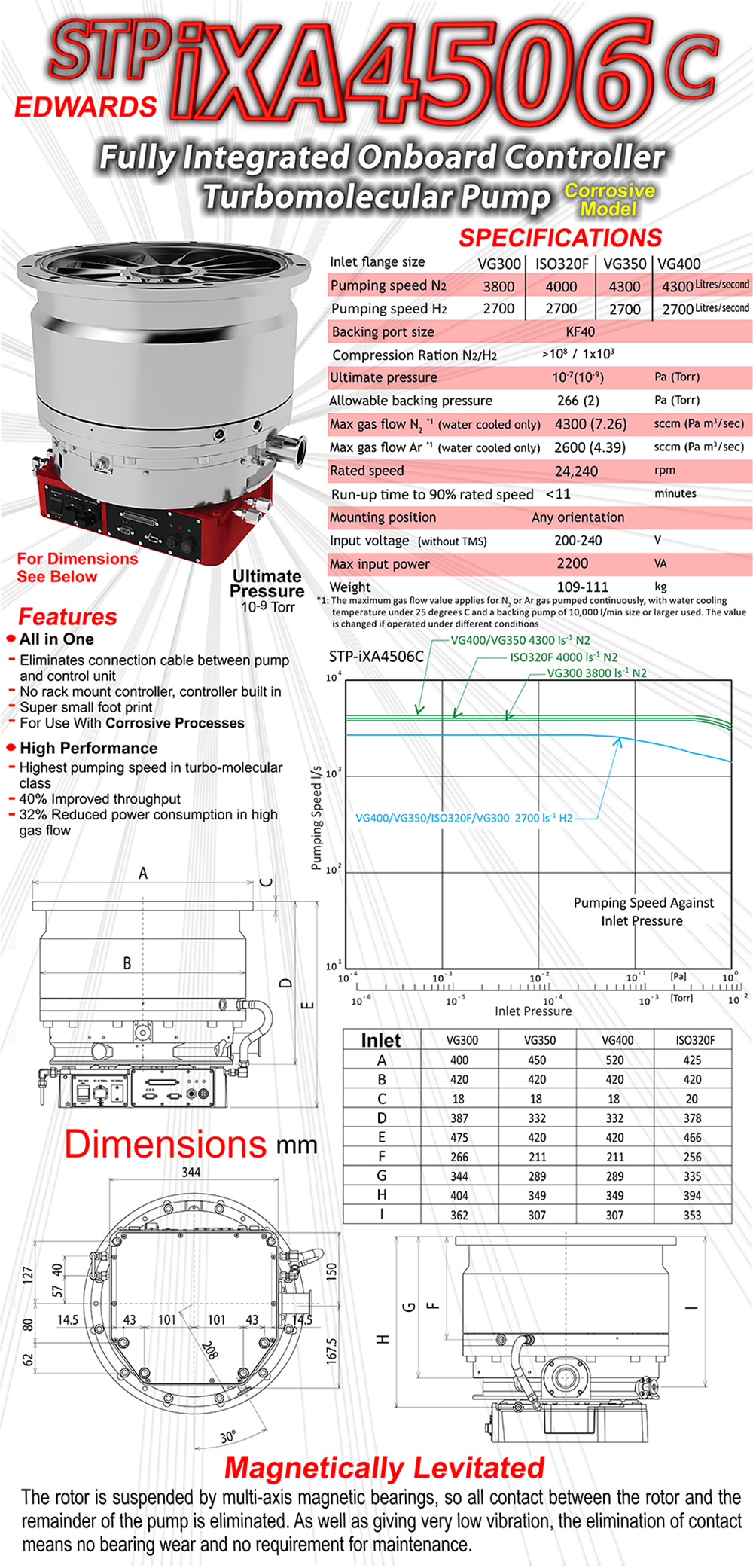

Edwards STP iXA4506C 5-axis Magnetic Bearing Turbo-Molecular Pump Corrosive, VG350 Inlet

All in One

-Eliminates connection cable between pump and control unit

-No rack mount controller, controller built in

-Super small foot print

-For Use With Corrosive Processes

High Performance

-Highest pumping speed in turbo-molecular class

-40% Improved throughput

-32% Reduced power consumption in high gas flow

$50,439.60 $63,049.50

The STP iXA4506C Maglev turbo-molecular pump utilizes a magnetic bearing and motor drive system and has an ultimate pressure of 10-9 Torr. This integrated controller series can be fully interfaced with advanced controllers to operate on a wide range of applications and processes. It eliminates the need for a conventional, rack-mounted controller and interconnecting cables. The fully integrated product offers easy installation and small footprint as an all-in-one solution for all application tools. The rotor is entirely suspended by magnetic bearings so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for consequent pump maintenance.

Achieving world-class pumping speed of 4300 l/s (N2) and throughput up to 4300 sccm (N2), on a 12-16 inch (300-400 mm) inlet flange, makes the STP-iXA4506C the ideal choice for a wide range of large volume high flow applicaitons. The STP iXA4506C can be connected directly to a terminal using a serial port and the STP-link Monitoring Software. The Software Displays, Rotational Speed, Motor Status, Temperature, Rotor balance status and Magnet bearing current.

CORROSION RESISTANT:

This pump has nickel coated rotors and stators and pump internals are suitable for corrosive gas applications. This ensures a high level of resistance to corrosion.

MAGNETIC BEARING TECHNOLOGY:

The rotor is suspended by multi-axis magnetic bearings, so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for maintenance.

VIBRATION FREE:

Magnetic levitation of the rotor results in an extremely low level of noise and vibration. Peakto- peak vibration level is less than 0.02 μm. This amplitude remains constant throughout the life of the pump and is free from troublesome subharmonics.

OIL FREE:

All STP turbomolecular pumps are oil free. The use of magnetic bearings eliminates all hydrocarbon lubricants ensuring no contamination of the vacuum process from the turbomolecular pump. This feature is vital in industry and in surface science or high energy physics applications (where even minute degrees of contamination disrupt measurements).

MAINTENANCE FREE:

Unlike conventional mechanical bearings, magnetic levitation means there is no frictional contact, eliminating sources of wear and vibration. This feature enables STP turbomolecular pumps to run for years with virtually no maintenance, reducing annual operating costs to a minimum and ensuring maximum up-time is achieved. This maintenance free feature can be particularly beneficial on processes producing chemical or radioactive contamination.

AUTOMATIC BALANCING SYSTEM (ABS):

ABS is a unique patented development of 5-axis technology. If any rotor imbalance is introduced (by deposition of process by-products, for example), sensors in the pump detect changes in the rotor motion and compensate the magnetic bearing fields to allow the rotor to spin on its natural inertial axis. This minimises the vibration transmitted to the inlet flange. ABS works at all pump rotational speeds.

SAFETY BACKUP BEARINGS:

STP pumps have dry lubricated axial and radial mechanical bearings as safety backup bearings. These support the rotor and protect the pump in the event of a total disruption of magnetic suspension or a massive air inrush which overcomes the magnetic bearing stiffness. These high precision ball bearings are dry lubricated and are not in contact with the rotor during normal operation..

The STP-iXA4506C can be used for a variety of applications including but not limited to:

-Plasma etch (chlorine, fluorine and bromine chemistries) for metal (aluminum), tungsten and dielectric (oxide) and polysilicon

-Electron cyclotron resonance (ECR) etch

-Film deposition CVD, PECVD, ECRCVD, MOCVD

-Sputtering

-Ion implantation source, beam line pumping end station

-MBE

-Diffusion

-Photo resist stripping

-Crystal/epitaxial growth

-Wafer inspection

-Load lock chambers

-Scientific instruments: surface analysis, mass spectrometry, electron microscopy

-High energy physics: beam lines, accelerators

-Radioactive applications: fusion systems, cyclotrons

| lnlet flange size | VG300 | ISO320F | VG350 | VG400 | |

| Pumping speed N2 | litres/second | 3800 | 4000 | 4300 | 4300 |

| Pumping speed H2 | litres/second | 2700 | 2700 | 2700 | 2700 |

| Backing port size | KF40 | ||||

| Compression ratio N2/H2 | >10 8/ 1 x 10 3 | ||||

| Ultimate pressure | Pa (Torr) | 10 -7(10 -9) | |||

| Allowable backing pressure | Pa (Torr) | 266 (2) | |||

| Max gas flow N2 *1(water cooled only) | sccm (Pa m3/sec) | 4300 (7.26) | |||

| Max gas flow Ar *1(water cooled only) | sccm (Pa m3/sec) | 2600 (4.39) | |||

| Rated speed | rpm | 24240 | |||

| Run-up time to 90% rated speed | minutes | <11 | |||

| Mounting position | Any orientation | ||||

| lnput voltage (without TMS) | V | 200-240 | |||

| Maximum input power | VA | 2200 | |||

| Weight | kg | 109-111 | |||